At present, transparent LED screen display is in the factory situation, and the cost is not cheap. Although the theoretical life span is 100,000 hours, in fact, after about 5,000 to 10,000 hours of operation, the uniformity will deteriorate, start to become flowery, and the commercial value will decrease. After 15,000 to 20,000 hours, the commercial value is almost lost, resulting in a huge waste of social resources.

Therefore, whether before leaving our factory or after using it for a period of time, the point-by-point correction technology can greatly improve the uniformity of the display screen in a very short time and at a very low cost, and significantly improve the image quality.

Before being applied to the factory, point-by-point correction is a means of quality improvement, which means the improvement of competitiveness and the expansion of profit margins; after being used for a period of time, point-by-point correction can prolong the display effect of the full-color LED display, which is beneficial for users. Create more business value and reduce waste of resources.

There are two main types of mainstream point-by-point correction techniques:

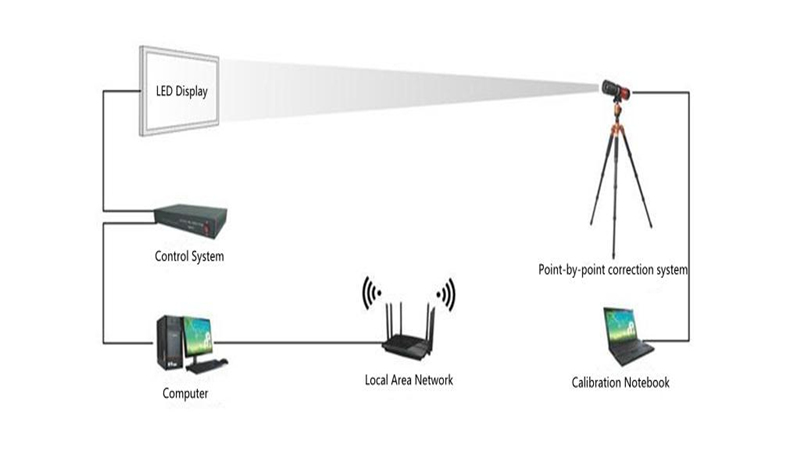

1. On-site point-by-point correction of transparent LED screen display

It is to operate the entire large screen that should be installed. Due to the influence of the environment, weather and technical compatibility problems in different places, the correction cost is high, especially the maintenance of some foreign orders.

2. LED cabinet calibration point by point of transparent glass LED Screen

At present, LED display manufacturers use cabinet-by-point calibration, which is a test procedure that must be passed before the LED transparent screen leaves the factory. dreamroad LEDs’ cabinet calibration technology is at the forefront of the industry, and the transparent screen has strong adaptability to various environments. The display effect is consistent.

The following focuses on the point-by-point calibration of the cabinet:

Cabinet calibration is the last step before leaving the factory. It is mainly used to eliminate the brightness and chromaticity differences between the cabinet and the cabinet, and improve the uniformity of the LED display after splicing.

In addition to adding calibration steps in the production process,we generally need to follow up on the calibration effect of the screen cabinet when it leaves the factory.

There are three commonly used methods:

First is to splicing all the cabinets together to observe the display effect, but the workload of splicing is relatively large, which is inconvenient to realize;

Second is to randomly select some cabinets for splicing and observe the correction effect;

Third is to use the measurement data recorded by the calibration system to simulate and evaluate the calibration effect of all cabinets. Added LED production lines for cabinet calibration and simulation evaluation/sampling inspection.

Similar to on-site calibration, for each cabinet, the process of cabinet calibration includes data acquisition, data analysis, target value setting, correction coefficient calculation and coefficient upload, and also requires the cooperation of the control system.