Theoretically, the service life of the LED display is greater than 100000 hours, even if 24 hours a day without interruption, the equivalent life theory is more than 10 years, the half-life is about 50,000 hours, how long the actual use of the product is closely related to the environment and LED screen maintenance.

When customers purchase high-quality LED displays, also need to pay attention to the supplier’s pre-sales and after-sales service, which can reduce the cost of maintenance later.

Our company will provide a 3-year warranty, within the warranty period, customers who have damaged modules can send them back to our factory for free repair.

There are internal and external factors affecting the life of the LED display:

Internal factors include the performance of the LED lamp, the performance of peripheral components, the anti-fatigue performance of the product, and external factors include the working environment of the LED display.

LED lamps are the most critical and life-time related components of the display, for LED, we focus on the following indicators:

Attenuation characteristics, anti-vapor penetration characteristics, anti-UV performance.

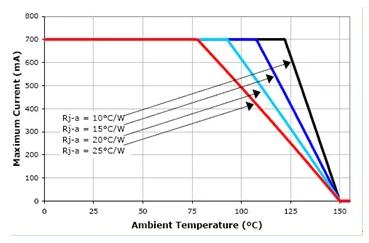

Brightness attenuation is the inherent characteristic of LED.

For a design life of 5 years of the display, if the brightness of the LED used to decay 50% in 5 years, in the design should be considered to set aside a margin of decay, otherwise, the display can not meet the standard after 5 years.

Outdoor displays are often subject to the erosion of moisture in the air, LED chips in contact with water vapor can cause stress changes or electrochemical reactions leading to device failure.

In addition, under ultraviolet radiation, LED colloid, support material properties will change, leading to device cracking, which in turn affects the life of the LED. So the LED used in outdoor UV resistance is also one of the important indicators.

So the outdoor LED display waterproof treatment must be done, and the protection level should reach IP65 in order to achieve waterproof, dustproof, sun protection, and other effects.

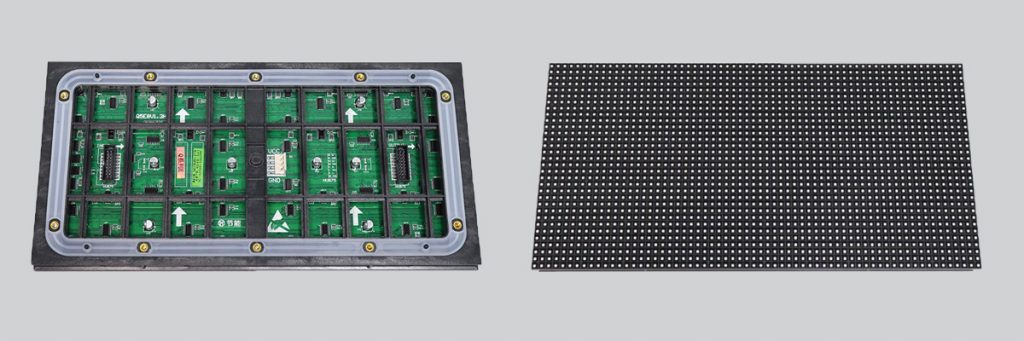

Not only LED chips, but the display also uses many other peripheral component materials, including circuit boards, plastic housings, switching power supplies, connectors, enclosures, etc. Problems with any one component may lead to a reduction in the life of the display.

So it is especially important to choose a good material. In addition, how fatigue resistance of the display product depends on the production process.

The poor triple anti-treatment process to produce the module anti-fatigue performance is difficult to ensure, in the temperature and humidity changes, the circuit board protection surface will appear to cracks, resulting in a decline in protection performance.

So, it is very important to maintain the display. Here are some ways to maintain the led display:

1. Check the fixity of the internal components of the LED display screen body. Damaged parts should be replaced in a timely manner.

When receiving weather changes and other natural disasters warnings, customers need to check the stability and security of the screen body components, if there are problems, need to fix the problems in time, so as to avoid unnecessary losses.

2. Do maintenance of the LED display and steel structure welding point surface coating regularly, which can prevent corrosion rust, and fall-off. LED display needs at least 2 times year maintenance.

3. The inspection of bad products: for bad products, we need to do a regular inspection, repair, or replacement, generally once every three months.

4. Clean the LED lamps in the process of LED display maintenance. When cleaning LED lamps, you can use a soft brush to scrub the dust accumulated outside the LED lamp gently.

5. If it is a waterproof case, you can also dip a little water to do the cleaning.

According to the use of LED display environment, we need to clean LED screen regularly can ensure the stable operation of the entire screen body.

6. Check the LED display lightning protection facilities frequently. Check the lightning rod and grounding lines regularly. It should be tested on the anti-tube after the occurrence of lightning.

If these devices fail to use, must be replaced in time. Besides, it needs to be checked during rainy periods.

7. Check the display screen power supply system.

The first step is to check the distribution box to see whether there is rust or loss in each connection of the line.

8. In order to safety, the grounding of the electrical box must ensure normal, and power lines and signal lines should be checked regularly to avoid the line being broken or chewed.

9. The whole power supply system also needs to be checked twice a year.

10. LED control system inspection. According to the various functions of pre-set situation, then test the control system.

11. All the lines and equipment of the screen should be checked regularly, so as to avoid unexpected situations. Check the reliability of the system regularly, e.g. every 7 days.

Any product has a life cycle and the LED display is also the same. The life of a product is not only related to the quality of its own raw materials, and production process but also closely related to the customer’s daily maintenance.

To extend the service life of the LED display, people must develop the habit of LED screen maintenance in the process of use, so as to reduce losses, and then it can be used for a longer time.